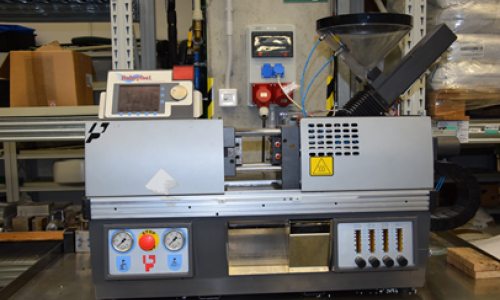

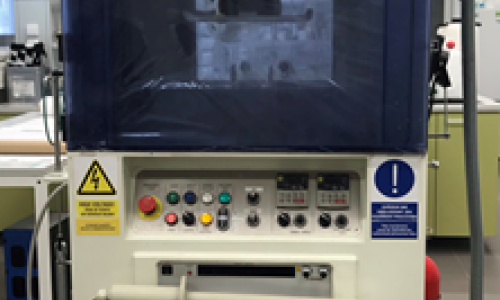

Electric bi-component injection moulding machine (FB140T)

Device is for:

Mixing and injection element of main unit – screw (D = 26 mm)

Mixing and injection element of side unit – screw (D = 26 mm)

Clamping force: 1200 kN

Specific injection pressure of main unit: 1980 bar

Specific injection pressure of side unit: 1730 bar

Max. injecting volume of main unit: 73 cm3 (PS)

Max. injecting volume of side unit: 65 cm3 (PS)

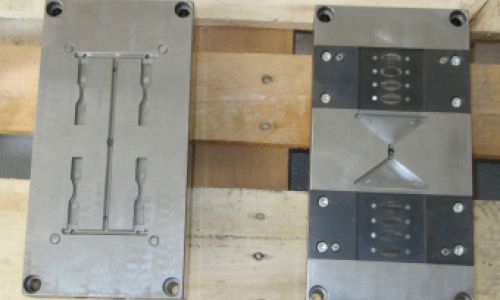

As a accessory two position unit for rotation of complete half of 2K mould.

contact person:

doc. Ing. Tomáš Sedláček, Ph.D.

+420 57 603 8012 A416

+420 724 434 581

This email address is being protected from spambots. You need JavaScript enabled to view it.

research