Polymer melt filament laboratory line, model LBS-300

Device is for:

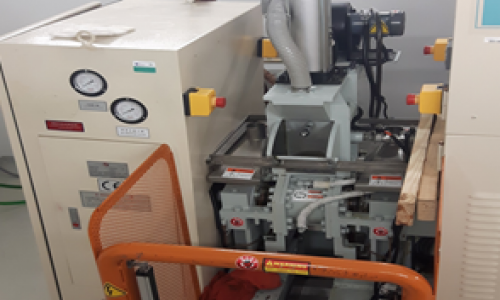

Laboratory line for continuous preparation of nonwoven textiles (spunbond, meltblown technology) from polymer melt filaments (e.g. PP, PLA, PA, PET) with high degree of process control.

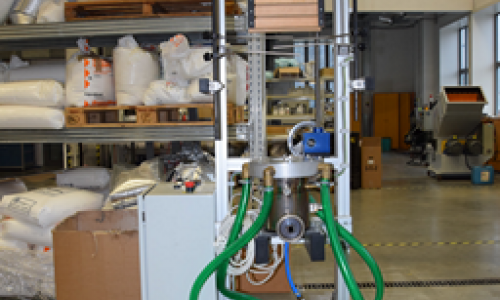

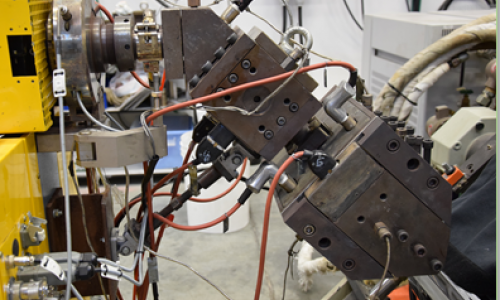

Line consists of 2 single screw extruders, gear pumps and pressure indicators. System is corrosion resistant in order to allow processing of fluoropolymers including inserts for filaments circular and irregular cross-section in configuration: homo-filament and bi-component filament (side by side, sheath/core, islands in the sea).

Single screw extruders have hopper containing vent for nitrogen purging of hydroscopic polymers, the throat of extruder is water cooled to prevent bridging, screw D=19 mm, L/D 30 with mixing element (Maddox). Max operating temperature is 450°C and extruder barrels are corrosion resistant in order to allow processing of fluoropolymers. Meltblown accessories:

Die 100 mm wide having 25 holes/1 inch (25.4 mm), corrosion resistant in order to allow processing of fluoropolymers. Haul-off conveyor with RPM regulation 100-1000 m/min.

Spunbond accessories:

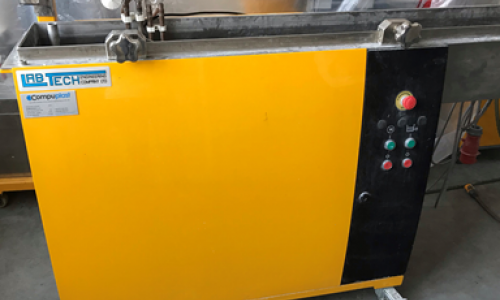

Slot type spunbond aspirator (150 mm wide), web collector for 125 mm webs belt conveyor type, heated calendar for spunbond. Filament accessories: Quench cabinet with variable speed blower and spin finish system, metered type, variable speed.

contact person:

doc. Ing. Tomáš Sedláček, Ph.D.

+420 57 603 8012 A416

+420 724 434 581

This email address is being protected from spambots. You need JavaScript enabled to view it.

research